Max Jensen's easy topslide swivel

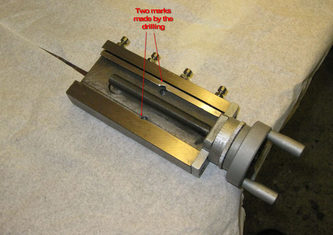

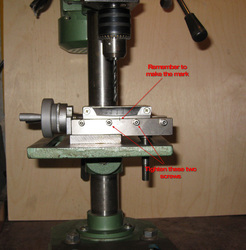

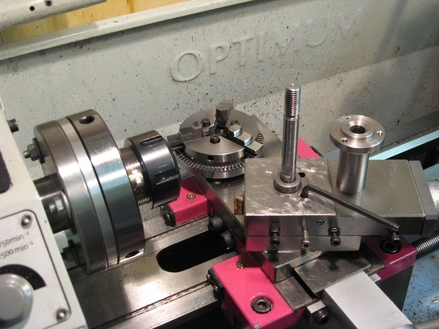

Max Jensen in Denmark has kindly contributed this simple way to make the topslide swivel easier to adjust. It also allows the whole topslide to be quickly removed from the lathe. His modification consists of two holes through the topslide, and witness marks to help position those holes over the socket head screws which clamp up the standard swivel disc. The holes are large enough to allow an Allen key to pass through. Max didn’t give his drill size, but the minimum size of hole for the Allen key is 4.5mm. He uses grubscrews to keep swarf out of the holes, so I guess he drilled 5mm and tapped M6. It would not take long for me to lose those grubscrews. A strip of thin plate simply resting on top of my topslide, located by two little spigots fitting down the holes would keep the swarf out, and might be easier to find when it fell into the chip tray. As well as the tapped holes, Max’s modification requires a little crescent shaped piece to be removed from the topslide gib strip so the Allen key can pass, but this is so small that the integrity of the gib strip is not affected. The final picture shows how Max used the gib screws to lock the slide, base and gib strip together, inverted the assembly and then drilled through, using the the existing holes in the base as a guide.This modification is much easier than mine. My thanks to Max for permission to show his pictures here. Click on any photo to enlarge it:

Marcello in Italy has modified his topslide along the same lines, as shown below. His holes are positioned so his topslide doesn't need to be moved very far from its usual working position to put the holes over the swivel bolts. Obviously, Marcello's QCTP covers the holes and keeps the swarf out, so rather than removing grubscrews for access, he removes his toolpost.

I think I'll scrap my more complicated mod, and go for holes in the topslide. My way involved completely removing the swivel disc from the cross-slide, so fitting something in place of the topslide (e.g. to gain extra rigidity with a solid tangential toolholder or parting tool holder) wouldn't be easy.

Back to Home Page and the Index

Back to Home Page and the Index