GETTING THE GEAR COVER BACK ON AFTER THE MODIFICATIONS.

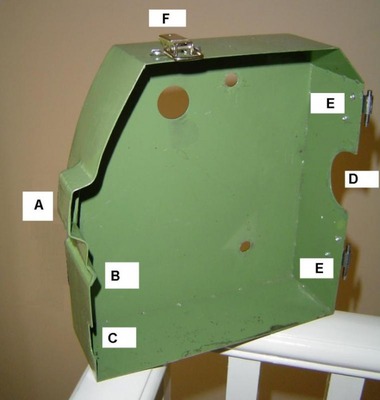

Many of the modifications shown in these pages interfered with the fit of the gear cover, so it was time for some metalbashing, followed by epoxy to stick new bits of metal on and filler to try and smooth out the irregularities. Here is the result:

Many of the modifications shown in these pages interfered with the fit of the gear cover, so it was time for some metalbashing, followed by epoxy to stick new bits of metal on and filler to try and smooth out the irregularities. Here is the result:

A is a bulge to accommodate the gears on the banjo when this is swung out to mesh its topmost gear with my reversing gear.

B is a channel to accommodate the actuating rod for my semi-auto saddle stop.

C is a cut-away for the T-handled bolts I have fitted to my regular and fine-feed banjos.

D is cut away for the T-handled bolt fitted to tension the drive belts as part of my easier speed change. The cutout is big, to give clearance for the cover to clear the T-handle when swing open on its hinges.

E and E are lift-off hinges, made from one side of a cheap hinge sawn in two. They fit into sockets (made from the other side of the hinge) pop-riveted to the electrics box cover. One pin is longer than the other, which helps when slotting the cover on.

F is one side of a toggle clip from the DIY shop. The other part of the clip is fastened to the top of the headstock. This holds the cover securely shut.

The hinges and the clip are very convenient, making it easy to close and fix the cover. This in turn is a safety measure – there’s less temptation to leave the cover off if you don’t have to find where you left the nuts which hold it on, and then fit them.

Useful things, toggle clips. Here’s another, securing the end of the chip guard to the lathe bed. It replaces an almost inaccessible socket-head screw which lived inside the guard.

B is a channel to accommodate the actuating rod for my semi-auto saddle stop.

C is a cut-away for the T-handled bolts I have fitted to my regular and fine-feed banjos.

D is cut away for the T-handled bolt fitted to tension the drive belts as part of my easier speed change. The cutout is big, to give clearance for the cover to clear the T-handle when swing open on its hinges.

E and E are lift-off hinges, made from one side of a cheap hinge sawn in two. They fit into sockets (made from the other side of the hinge) pop-riveted to the electrics box cover. One pin is longer than the other, which helps when slotting the cover on.

F is one side of a toggle clip from the DIY shop. The other part of the clip is fastened to the top of the headstock. This holds the cover securely shut.

The hinges and the clip are very convenient, making it easy to close and fix the cover. This in turn is a safety measure – there’s less temptation to leave the cover off if you don’t have to find where you left the nuts which hold it on, and then fit them.

Useful things, toggle clips. Here’s another, securing the end of the chip guard to the lathe bed. It replaces an almost inaccessible socket-head screw which lived inside the guard.

After all these alterations, the gear cover needed repainting. A mini-can of "Warco Green" came with the lathe, but soon ran out. Dulux etc colour charts didn't disclose a match, but Internet research revealed that this particular shade features in the German RAL colour classification system as RAL 6011 "Reseda Green". Johnstone's Paints have a retail outlet nearby, and RAL 6011 is known to their computerised mixing system, so they made up a can of gloss for me. 700ml will be enough to repaint the whole lathe several times over. It's good paint, too.