THE WARCO WM180: BETTER METRIC THREADS FROM A 12 TPI LEADSCREW.

My WM180 lathe has an imperial 12TPI leadscrew. Until I peeled it off, a chart on the front gave gear combinations for cutting various imperial and metric pitches, the latter being approximations. I wondered how accurate the suggestions for metric threads really were, and checked them. They weren’t too bad, except for 0.5mm, where my calculations showed that the recommended gears would produce 0.454mm, 10% out. There is a misprint on my chart – if a 33T gear is substituted for the 30T it suggests, the result is much better.

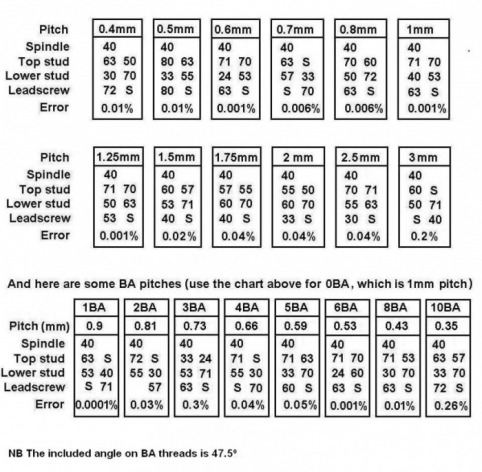

Being by now imbued with enthusiasm for the arithmetic involved, I worked out my own chart, as shown below, to produce as close to true metric as I could get with my stock changewheels. These were 24, 30, 33, 40, 50, 53, 55, 57, 60, 63, 70, 71, 72 and 2 x 80 tooth. There was a second 24T, not used for any imperial or metric thread, so I pressed it into service on my dedicated fine feed banjo.

Getting back to the main theme, the suggestions on the supplied chart use a single compound gear (two gears locked together and revolving together on the same stud) plus an idler. Though more accurate, most set-ups on my chart involve two compound gears, and will thus take longer to set up.

The tables represent the side view of the changewheels seen by the operator. “S” represents a spacer – either the one supplied for the leadscrew, or a small gear (e.g. 24T) placed on the top banjo stud for 0.7mm and 3mm pitches.

The results are pretty accurate, apart from 3mm pitch, where I could get no better than 0.2% error.

While in mathematical mood, I worked out some combinations for BA threads, which are also shown below.

Being by now imbued with enthusiasm for the arithmetic involved, I worked out my own chart, as shown below, to produce as close to true metric as I could get with my stock changewheels. These were 24, 30, 33, 40, 50, 53, 55, 57, 60, 63, 70, 71, 72 and 2 x 80 tooth. There was a second 24T, not used for any imperial or metric thread, so I pressed it into service on my dedicated fine feed banjo.

Getting back to the main theme, the suggestions on the supplied chart use a single compound gear (two gears locked together and revolving together on the same stud) plus an idler. Though more accurate, most set-ups on my chart involve two compound gears, and will thus take longer to set up.

The tables represent the side view of the changewheels seen by the operator. “S” represents a spacer – either the one supplied for the leadscrew, or a small gear (e.g. 24T) placed on the top banjo stud for 0.7mm and 3mm pitches.

The results are pretty accurate, apart from 3mm pitch, where I could get no better than 0.2% error.

While in mathematical mood, I worked out some combinations for BA threads, which are also shown below.